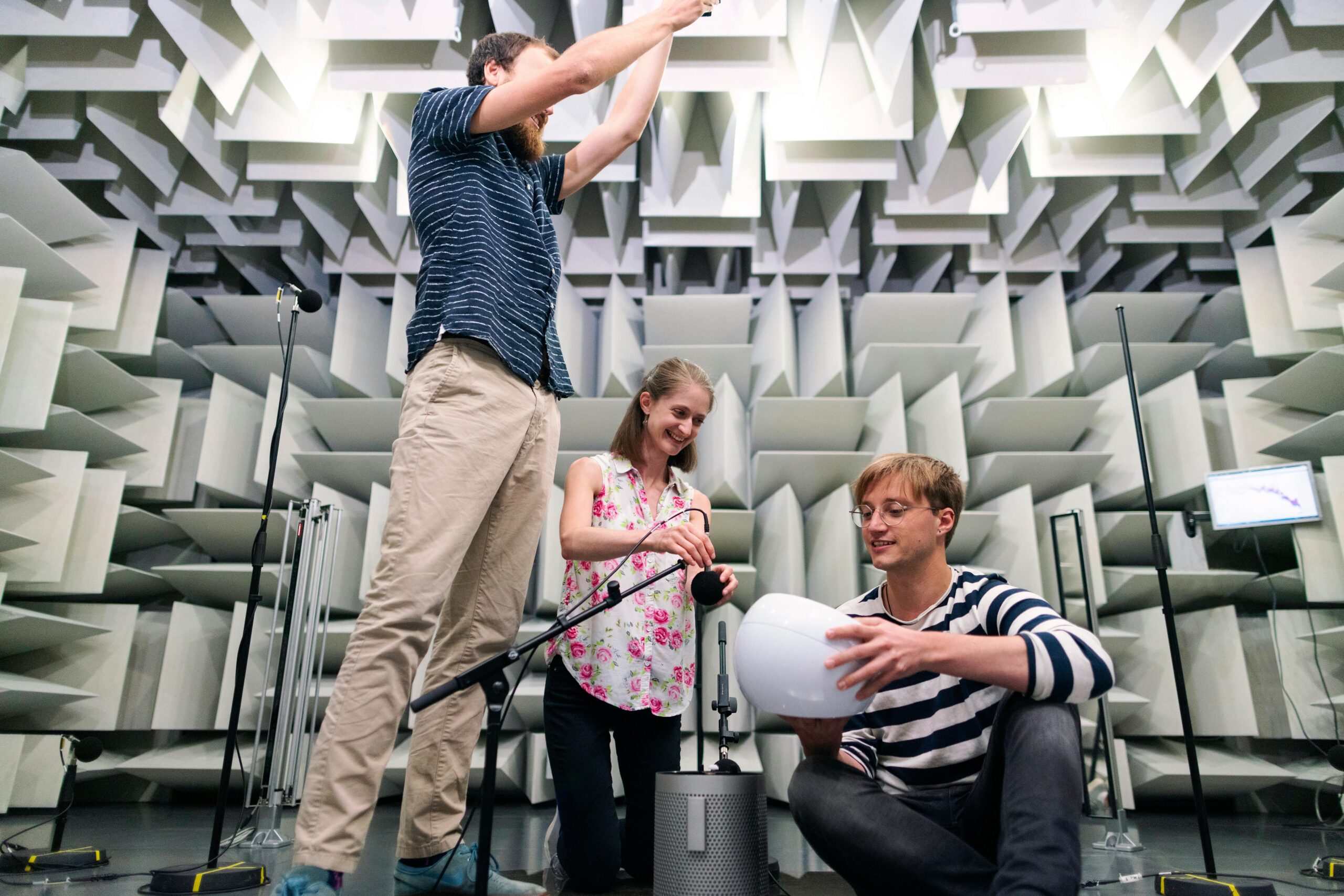

Accurate noise measurement begins with properly calibrated microphones. Without calibration, your data becomes unreliable, leading to flawed decisions and potential compliance issues.

🎯 Why Microphone Calibration Matters More Than You Think

In the world of acoustic measurement, precision isn’t just a nice-to-have feature—it’s the foundation of every reliable result. Whether you’re conducting environmental noise assessments, workplace safety evaluations, or audio engineering projects, the accuracy of your measurements depends entirely on proper microphone calibration.

Microphones, like all measurement instruments, drift over time. Temperature changes, humidity, physical wear, and even transportation can affect their sensitivity. A microphone that was perfectly accurate yesterday might be off by several decibels today, and in noise measurement, even a 1 dB difference can be significant.

Professional acousticians understand that uncalibrated microphones render data essentially worthless. Imagine making critical decisions about noise control investments, legal compliance, or community health based on measurements that are off by 3-5 dB. The consequences could range from wasted resources to serious legal liability.

Understanding the Fundamentals of Acoustic Calibration

Microphone calibration establishes a known reference point against which all subsequent measurements are compared. The process involves exposing the microphone to a precisely controlled sound pressure level and adjusting the measurement system to read correctly.

Most calibration procedures use a device called an acoustic calibrator, which generates a stable, known sound pressure level—typically 94 dB or 114 dB at 1000 Hz. When placed over the microphone, the calibrator creates a sealed acoustic environment where the sound level is consistent and traceable to national standards.

The Science Behind Sound Pressure Levels

Sound pressure level is measured in decibels (dB), a logarithmic scale that represents the ratio between measured sound pressure and a reference pressure of 20 micropascals. This reference corresponds to the threshold of human hearing at 1000 Hz.

Because the decibel scale is logarithmic, small numerical differences represent significant actual differences. A 3 dB increase represents a doubling of sound energy, while a 10 dB increase is perceived as roughly twice as loud by human ears. This makes accurate calibration critical—even small errors compound quickly.

Types of Microphone Calibration Methods

Different applications and accuracy requirements call for different calibration approaches. Understanding these methods helps you choose the right one for your specific needs.

Field Calibration: On-Site Verification 🔧

Field calibration is performed before and after each measurement session using a portable acoustic calibrator. This quick check ensures your microphone hasn’t drifted since its last laboratory calibration and verifies the entire measurement chain is functioning properly.

The process takes only seconds but provides essential verification. You place the calibrator over the microphone, activate it, and confirm the meter reads the expected value (usually 94 dB or 114 dB, depending on your calibrator). If the reading is off, you adjust the measurement system accordingly.

Field calibration doesn’t replace laboratory calibration but complements it by catching day-to-day variations and verifying system integrity immediately before critical measurements.

Laboratory Calibration: Traceable Standards

Laboratory calibration is more comprehensive and performed by accredited facilities using equipment traceable to national or international standards. These calibrations typically occur annually or after any event that might affect microphone performance, such as drops, extreme environmental exposure, or suspected damage.

During laboratory calibration, technicians test the microphone across its entire frequency range and at multiple sound pressure levels. They document the microphone’s actual response compared to its nominal specifications, providing a calibration certificate that shows traceability to standards maintained by organizations like NIST or NPL.

This documentation is often required for legal, regulatory, or quality assurance purposes. Many industries mandate annual laboratory calibration for compliance with standards like ISO, OSHA, or EPA regulations.

Step-by-Step Guide to Proper Microphone Calibration

Executing proper calibration requires attention to detail and understanding of the process. Here’s a comprehensive walkthrough for field calibration, the type most practitioners perform regularly.

Pre-Calibration Preparation

Before beginning calibration, allow your equipment to stabilize to ambient conditions. If you’ve just brought equipment from a cold vehicle into a warm building, wait at least 15-20 minutes. Temperature differentials can affect both microphone sensitivity and calibrator output.

Inspect your microphone for physical damage, contamination, or moisture. Clean the microphone capsule gently if needed, using only approved cleaning materials. Even a thin layer of dust or moisture can affect measurements by several decibels.

Check your calibrator’s battery level. Low batteries can cause calibrator output to drift, making your calibration inaccurate. Most quality calibrators have battery indicators—replace batteries if there’s any doubt.

The Calibration Process

Turn on your sound level meter and allow it to warm up according to manufacturer specifications, typically 2-5 minutes. Set the meter to the appropriate weighting (usually A-weighting for general noise measurement) and time constant (Fast, Slow, or Impulse as appropriate).

Place the acoustic calibrator firmly over the microphone, ensuring a good seal. The calibrator should fit snugly without gaps—any leakage will reduce the sound pressure level and compromise calibration accuracy.

Activate the calibrator and wait for the sound level meter reading to stabilize. This usually takes just a few seconds. The display should show the calibrator’s nominal output level (94 dB or 114 dB). If it doesn’t, adjust the meter’s calibration control until it does.

Record the calibration in your measurement log, noting the date, time, equipment serial numbers, and any adjustment made. This documentation is essential for quality assurance and may be required for legal or regulatory purposes.

Common Calibration Mistakes and How to Avoid Them ⚠️

Even experienced practitioners sometimes make calibration errors that compromise measurement accuracy. Being aware of these pitfalls helps you avoid them.

Skipping Pre-Measurement Calibration

Some operators calibrate only once at the beginning of the day, then conduct multiple measurements without rechecking. Environmental conditions change, batteries deplete, and equipment drifts. Always calibrate immediately before critical measurements and verify calibration afterward to ensure your data remained valid throughout the session.

Ignoring Environmental Factors

Temperature, humidity, and barometric pressure all affect sound propagation and microphone sensitivity. Extreme conditions can cause measurements to drift beyond acceptable tolerances. While field calibration compensates for many of these effects, be aware that operating equipment outside its specified environmental range may produce unreliable results even with proper calibration.

Using Damaged or Dirty Equipment

A microphone with a dented grille, corroded connector, or contaminated diaphragm cannot be reliably calibrated. The calibration might show correct readings at the calibrator’s specific frequency (1000 Hz), but the microphone’s response at other frequencies may be severely compromised. Regular inspection and maintenance are as important as calibration itself.

Advanced Calibration Considerations for Professional Applications

As your noise measurement needs become more sophisticated, you’ll encounter situations requiring deeper understanding of calibration principles.

Frequency-Specific Calibration

Standard field calibrators operate at a single frequency—usually 1000 Hz. This verifies overall sensitivity but doesn’t confirm the microphone’s frequency response remains accurate across the audio spectrum. Laboratory calibration tests multiple frequencies, revealing whether the microphone maintains proper response characteristics throughout its range.

For applications requiring precise frequency analysis—such as detailed acoustic studies, audio engineering, or building acoustics—ensuring proper frequency response is critical. Your calibration certificate should document frequency response, and you should have it re-verified annually.

Understanding Uncertainty and Traceability

Every measurement contains some uncertainty—the range within which the true value lies. Your calibration certificate should specify measurement uncertainty, typically expressed as ± a certain number of decibels at a specific confidence level (usually 95%).

For legal or regulatory applications, traceability to national standards is often required. This means your calibrator must itself be calibrated by an accredited laboratory, creating a documented chain of traceability back to fundamental reference standards. This chain ensures your measurements can be defended if challenged.

Selecting the Right Calibration Equipment 🎚️

Your calibration equipment must match or exceed the accuracy requirements of your measurements. A Class 1 sound level meter requires a Class 1 calibrator; using lower-grade equipment compromises the entire measurement system.

Acoustic calibrators are classified by their accuracy. Class 1 calibrators typically have uncertainties of ±0.3 dB or better, while Class 2 calibrators may have uncertainties around ±0.5 dB. While this difference seems small, it matters significantly when measurement results approach regulatory limits or when making comparative measurements over time.

Consider calibrator features beyond basic specifications. Battery life, ruggedness, and compatibility with various microphone sizes all affect field usability. Some calibrators offer multiple output levels or built-in environmental monitoring, features that may be valuable depending on your applications.

Maintaining Calibration Between Laboratory Services

The period between annual laboratory calibrations is crucial. Your equipment must remain accurate throughout this time, which requires proper care and regular verification.

Storage and Transportation

Store microphones in protective cases with desiccant to control humidity. Avoid extreme temperatures and never leave equipment in vehicles where conditions fluctuate dramatically. Physical shock during transportation can damage sensitive components, so use padded cases designed for measurement equipment.

Regular Performance Checks

Beyond daily field calibration, periodically perform more comprehensive checks. Compare your microphone against a reference microphone if available, or conduct repeated measurements of a stable noise source to verify consistency over time. Significant variations suggest the need for laboratory calibration even before the annual service is due.

Digital Tools for Modern Calibration Management 📱

Modern technology offers digital solutions for tracking calibration history, scheduling maintenance, and documenting compliance. Several professional-grade applications help acousticians manage their calibration programs effectively.

These tools can store calibration certificates, set reminders for upcoming calibrations, and generate reports for quality management systems. Some integrate directly with measurement equipment, automatically logging calibration data and flagging instruments that fall outside acceptable tolerances.

Industry Standards and Regulatory Requirements

Various standards govern microphone calibration depending on your industry and jurisdiction. Understanding applicable requirements ensures compliance and defensibility of your measurements.

International standards like IEC 61672 specify performance requirements for sound level meters, including calibration procedures and verification intervals. Occupational safety regulations often reference these standards, making compliance mandatory for workplace noise assessments.

Environmental noise regulations may require specific calibration documentation and procedures. Before conducting measurements for regulatory purposes, verify which standards apply and ensure your calibration program meets those requirements. Documentation is as important as the calibration itself—if you can’t prove proper calibration, your measurements may be rejected.

Building a Sustainable Calibration Program

Effective calibration isn’t a one-time event but an ongoing program integrated into your quality management system. This program should include documented procedures, scheduled calibrations, record-keeping systems, and regular audits.

Document your calibration procedures in writing, specifying who performs calibrations, how often, under what conditions, and what actions to take when readings fall outside tolerances. This documentation demonstrates your commitment to quality and provides consistency across different operators.

Schedule calibrations proactively rather than reactively. Calendar reminders for annual laboratory calibrations, battery replacements, and equipment inspections prevent last-minute scrambles and ensure continuous readiness.

Maintain comprehensive records including calibration certificates, field calibration logs, maintenance history, and any incidents that might affect equipment performance. These records prove due diligence and provide valuable historical data for tracking equipment performance trends.

The Future of Acoustic Calibration Technology 🚀

Calibration technology continues evolving, with innovations making the process more convenient, accurate, and integrated. Automated calibration systems can now perform unattended verification, while advanced signal processing techniques enable more sophisticated analysis of microphone performance.

Wireless connectivity allows remote monitoring of calibration status, with some systems sending automatic alerts when calibration is due or when equipment drifts outside specifications. Cloud-based documentation systems ensure calibration records are securely stored and accessible from anywhere.

Despite these technological advances, fundamental principles remain unchanged. Accurate noise measurement still requires traceable calibration, regular verification, proper equipment care, and operator competence. Technology enhances these practices but doesn’t replace them.

Achieving Measurement Excellence Through Proper Calibration

Mastering microphone calibration transforms your noise measurement practice from adequate to excellent. The difference between simply owning measurement equipment and truly understanding how to maintain its accuracy separates professionals from amateurs.

Reliable noise data supports better decisions, whether you’re protecting worker hearing, assessing environmental impacts, or optimizing acoustic designs. When stakeholders trust your measurements, your recommendations carry weight and drive meaningful improvements.

Commit to calibration excellence by establishing rigorous procedures, maintaining detailed records, and continuously educating yourself about best practices. Your measurements will gain credibility, your findings will withstand scrutiny, and your professional reputation will reflect the precision you bring to every project.

The investment in proper calibration—both equipment and training—pays dividends through increased confidence in results, reduced liability exposure, and enhanced professional standing. In acoustic measurement, precision isn’t perfectionism; it’s professional responsibility. Make calibration your foundation, and build reliable noise data that serves its intended purpose with unwavering accuracy.

Toni Santos is a sound researcher and ecological acoustician specializing in the study of environmental soundscapes, bioacoustic habitat patterns, and the sonic signatures embedded in natural ecosystems. Through an interdisciplinary and sensor-focused lens, Toni investigates how ecosystems communicate, adapt, and reveal their health through acoustic data — across landscapes, species, and harmonic environments. His work is grounded in a fascination with sound not only as vibration, but as carriers of ecological meaning. From ambient noise mapping techniques to bioacoustic studies and harmonic footprint models, Toni uncovers the analytical and sonic tools through which ecosystems preserve their relationship with the acoustic environment. With a background in environmental acoustics and ecological data analysis, Toni blends sound mapping with habitat research to reveal how ecosystems use sound to shape biodiversity, transmit environmental signals, and encode ecological knowledge. As the creative mind behind xyrganos, Toni curates acoustic datasets, speculative sound studies, and harmonic interpretations that revive the deep ecological ties between fauna, soundscapes, and environmental science. His work is a tribute to: The spatial sound analysis of Ambient Noise Mapping The species-driven research of Bioacoustic Habitat Studies The environmental link between Eco-sound Correlation The layered acoustic signature of Harmonic Footprint Analysis Whether you're an acoustic ecologist, environmental researcher, or curious explorer of soundscape science, Toni invites you to explore the hidden frequencies of ecological knowledge — one frequency, one habitat, one harmonic at a time.